Optimization of timber structures: Influence of connections behaviour and design

Driven by the development of the industry, with a range of new engineered timber products, and the will to promote the use of bio-based materials in buildings, timber construction is booming.

Wood has recently (re)emerged as a sustainable construction material for high-rise and long-span structures, much more in line with the intrinsic performances of the material and its high strength-to-weight and stiffness-to-weight ratios.

This fast development fosters today an extensive review of structural systems and constructive principles suited to the material’s specific properties and design process. While steel and concrete have shaped our city landscape for more than a century, timber cannot stand for a pure substitute, but it has to find its own structural and architectural expression.

How to optimize timber structures ?

As a result, a question arises: can we design, optimize, and build a timber structure the same way we do for steel? For instance, from the early stages of a project, joints are generally a critical factor in the design of timber structures.

Elioth, by Egis recently published in the journal Engineering Structures a study on the shape optimization of braced frames for tall timber buildings [1]. Based on a well-known case-study, this paper explores the influence of the semi-rigidity of timber connections on the overall mechanical behavior and design of high-rise structures.

[1] K. Mam, C. Douthe, R. Le, and F. Consigny, “Shape optimization of braced frames for tall timber buildings : Influence of semi-rigid connections on design and optimization process.,” Engineering Structures. vol. 216, no. April, p. 110692, 2020.

(c) Quickit //Art&Build

Project Silva, a wooden tower in Bordeaux (non-contractual rendering). The project consists of three buildings, including the tower Silva, with a height of 50 m and 18 floors, and its main timber structure. Developer: Kaufman & Broad ; Architects: Art&Build, Studio Bellecour

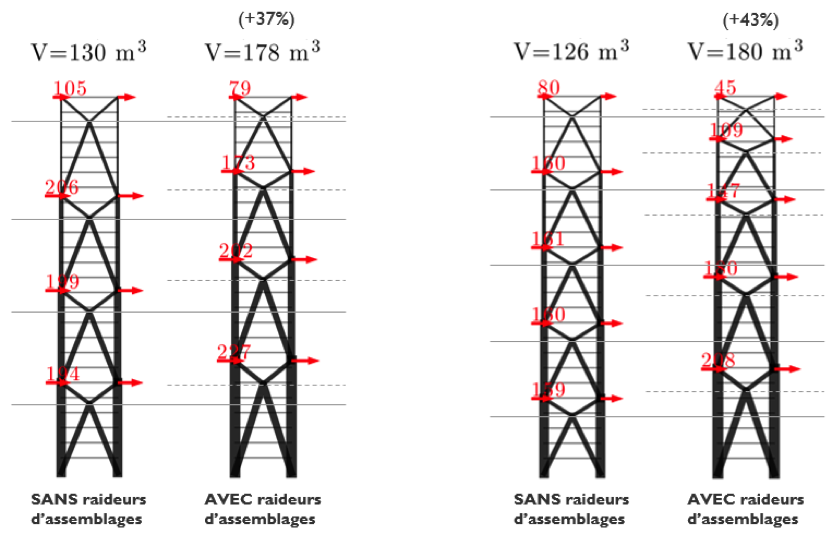

We study the optimal geometry – and sizing – of an X-braced frame structure part of the lateral system of a building as shown below. The frame has an overall height of 80 m and a width of 12 m and is composed of multiple bracing modules along the height. The height and the working point (intersection of the diagonals) of each module can vary.

Shape optimization of a braced frame with multiple modules along the height. Comparison of optimum geometry and volume of material with and without joint stiffness. (left) 4 modules ; (right) 5 modules.

The introduction of semi-rigid connections (each timber member is supposed to have dowel-type joints at both ends) has little influence on the optimum work point ratio of the modules, but leads inevitably to a significant increase of the timber volume. This seems to suggest that the number of connections should be reduced to limit the loss of stiffness due to connections in timber structures.

Furthermore, the semi-rigidity of connections influences the optimal distribution of modules height, from an equally distributed solution (i.e. all the modules have the same height) towards a solution with consecutive modules with decreasing height.

Connections in timber engineering: a core issue

This study is part of a larger research project on the structural and environmental exploration of high-span timber structures. The main objective is to highlight the balance between topological optimization (minimization of the material) and the need to rationalize our design to comply with timber properties.

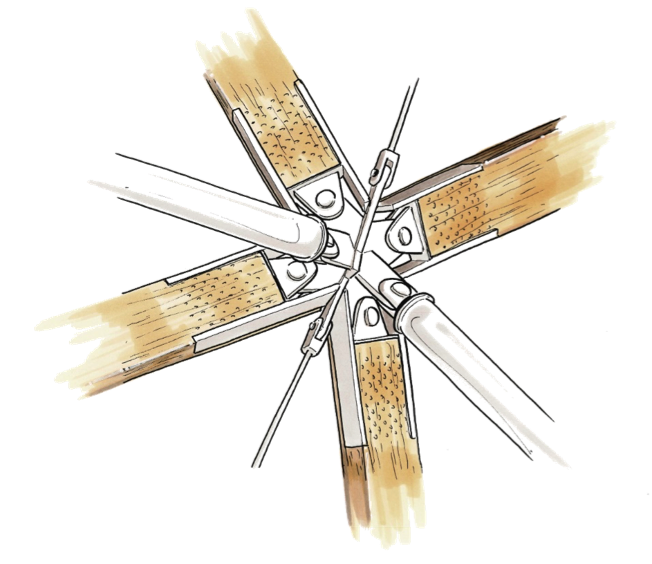

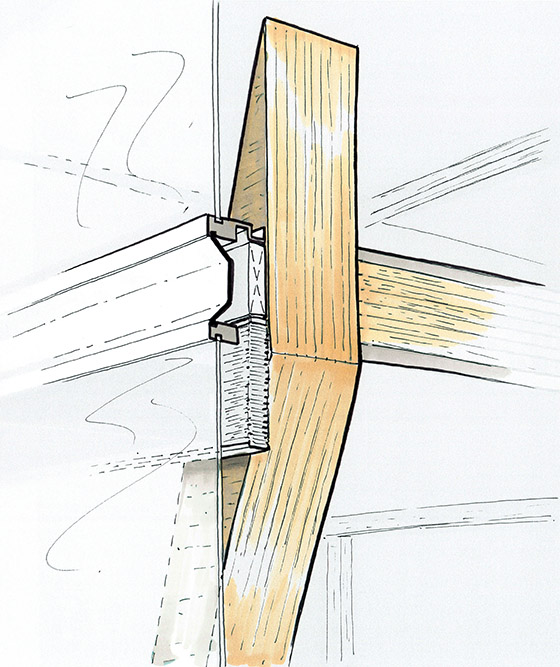

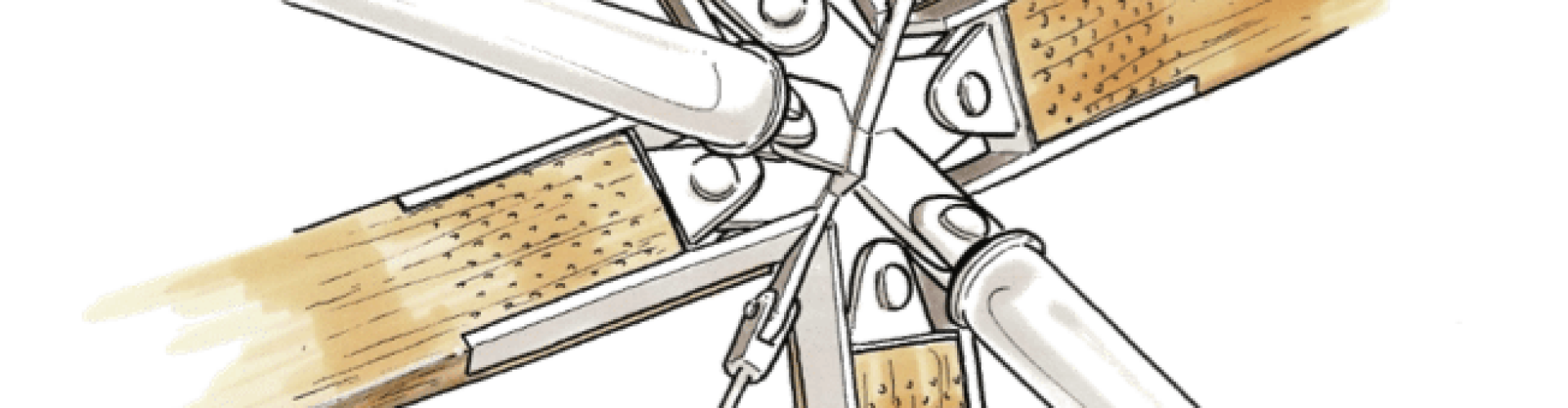

The impact of connections in timber engineering, whether in terms of structural behavior, cost or constructability cannot be overlooked. From a structural perspective, their strength can dictate the strength of the structure, their stiffness influences global deformations and member size can be determined by characteristics of the connector.

Timber connections also require complex manufacturing processes: steel, machining, milling… In this perspective, connections thus account for a major economic cost, but also a significant environmental burden.

Depending on the type of connection and technical choices, the amount of steel in timber structures can vary to a very large extent. Take the example of a structure made up of 1 m3 of glued laminated timber and a certain amount of steel (plates, bolt, screws, etc.) accounting for between 5% and 25% of the mass of wood. Using basic assumptions on material costs and global warming potentials (see below), we note that steel connections have a major impact on the total cost and carbon footprint of the structure.

Impact of the amount of steel in the connections on the cost and carbon footprint of a wooden structure.

Koliann Mam

Ingénieur Structure et Doctorant CIFRE

“Structural Engineer and CIFRE PhD student at Elioth, I have been working for 3 years on the structural and environmental exploration of large span timber structures. Whether in my thesis or on my projects at Elioth, I seek to integrate methods for the environmental assessment of structures into the design process and the search for high-performance solutions (materials, typologies, geometry, etc.). The growth of the wood industry and more broadly of bio-sourced products now offers the opportunity, not to abandon more traditional construction materials, but to improve, innovate and rethink our design methods for our structures, with the aim of promoting a mix of materials at all levels of the structure”