Allianz Riviera

City : Nice

Client : Nice Eco Stadium (Groupement PPP Vinci)

Team : VINCI Construction, Wilmotte & Associés, Egis Méditerranée, Egis Industrie et Elioth

Surface area : 45 000 m² de toiture (40 000 m² d’enveloppe, 50 m de porte-à-faux)

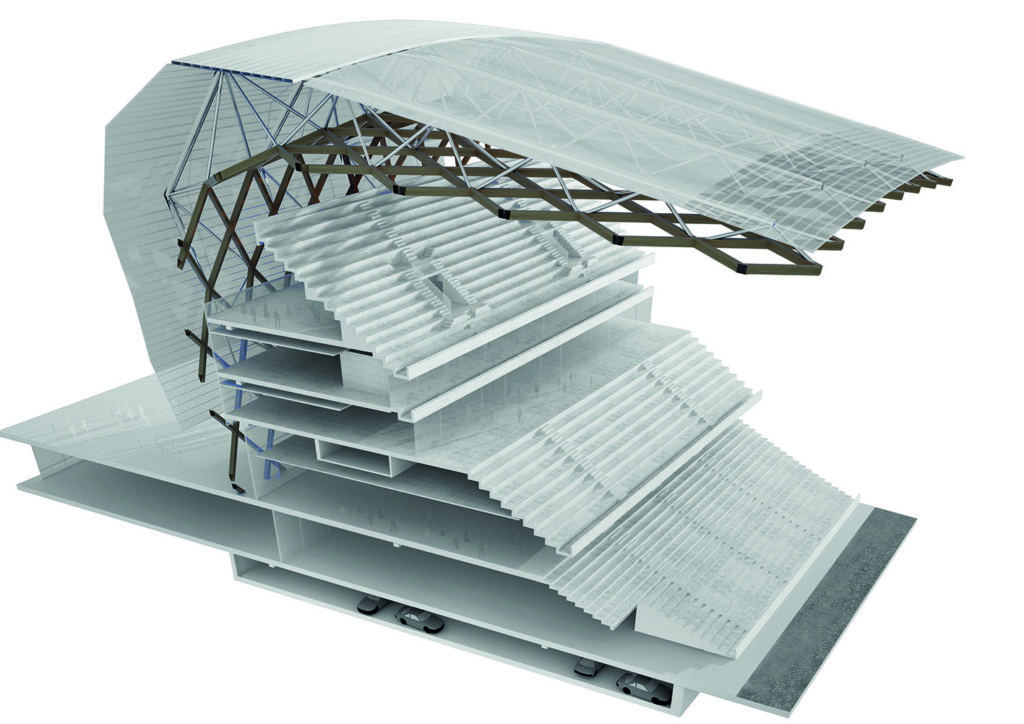

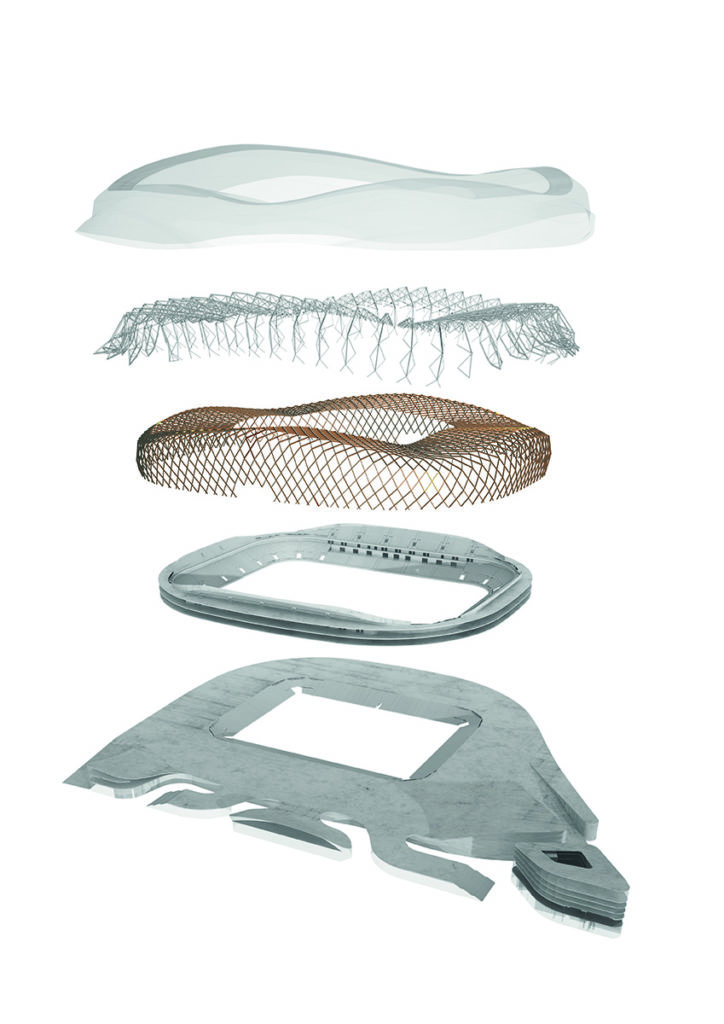

Structure, Facade, and Environment: the whole range of Elioth’s expertise has been merged to create the new Nice stadium. Inaugurated in September 2013, the Nice stadium Allianz Riviera was one of the host stadiums for the Euro 2016. With the project partners, Elioth took up challenge which is innovative whether though its geometry, its constructive standpoint, or environmental ambition. It is a key project in terms of sustainable development and technical performances: a mixed timber-steel structure with an ETFE covering, geothermal energy to produce heating and cooling, extensive use of natural ventilation, implementation of a photovoltaic power plant of 14 00kWp with an area of 8 500 m².

The undulating geometry of the stadium cover is given by the framework. For the membrane that covers it, it was not a question of creating forms with double curvature of great range, but rather of coming closest to the shape of this framework and of highlighting the screening and the facettisation.

The material of the facade is transparent to allow the visual link between the inside of the stadium and the plain of the var. Its envelope reveals the activity of the stadium to the users of the plain, and gives the reading of the landscape from this promontory that constitute the stadium and its peripheral corridors. The façade consists of single layer ETFE panels, supported by a cable network. This innovative implementation of the ETFE, developed on a surface of 25000 m², has led us to tap into the mechanical resources of the material. An ATEx procedure has guided the conduct of many material tests, such as bi-axial tensile tests to accurately characterize the different levels of ETFE creep.

The use of a non-curved membrane is a delicate process requiring a control of the tolerances of installation in order to ensure good tensioning of the fabric. To enable the adjustment of the prestressing, the panels are fixed to the framework by means of a system of threaded rods. Sealing flaps then cover the panels and are inserted into an edge profile. On the roof, transparency was not an imperative. On the contrary, it was necessary to protect the spectators from the Nice sun, and that is why we used a PVC coated polyester fiber fabric, more opaque than ETFE. The fabric is placed on arches which give it a double curvature: high enough to ensure efficient operation of the membrane, without disturbing the overall reading of the shape of the roof.

Design and Engineering of the steel roofing truss shell of the stadium (competition phase to handover)

Vincent LEREST

responsable adjoint pôles façades.