WOOD’UP (B1A3) - ZAC Paris Rive Gauche

City : Paris

Client : REI & Compagnie de Phalsbourg

Team : LAN Architecte / Elioth

Surface area: : 8000 m² floor space

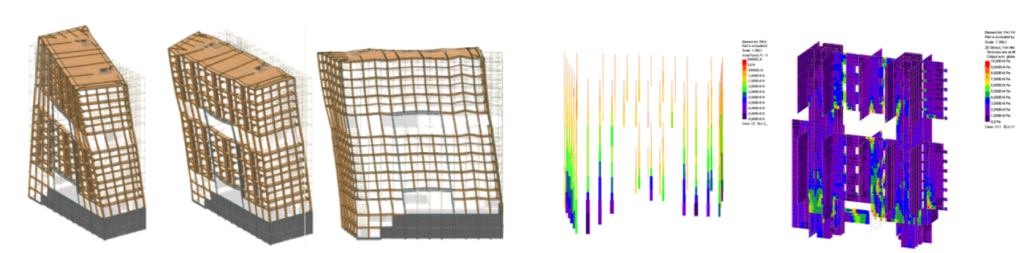

The project is a 17-floor student accommodation building with a structure made entirely of wood, situated on the banks of the river Seine and close to the Boulevard Périphérique. On this project, the aspect of ‘demonstrating wood’ has been respected to the letter: wood can be found and is visible everywhere. The position of the structure, built as an exoskeleton, requires the careful management of structural systems and junctions between interior and exterior; the design of the envelope must therefore deliver a required acoustic and energy performance which is achieved through the permanent dialogue between our three areas of expertise: Structure, Façade and Environment.

Studies and design of the structure: modelling and pre-sizing

Economic approach to various wooden structure solutions.

Inventing ways of integrating and protecting wood on a façade.

Express architecture while fulfilling the acoustic and pollution requirements of the location.

Environmental impact studies of the project.

The structure is made of Glulam for the posts and beams, and CLT for the floors and bracing walls.

This project asserts it singularity and modernity by displaying its wood façade, and promises long-term durability thanks to an unprecedented encapsulation technique.